One of the first major decisions that you will have to make about your t-shirt business is the t-shirt printing method.

The two most common ways are screen printing and direct to garment (DTG) printing. We’ve put together an extensive guide to help you figure out which option is right for your custom apparel business.

What is Screen Printing and How Does it Work?

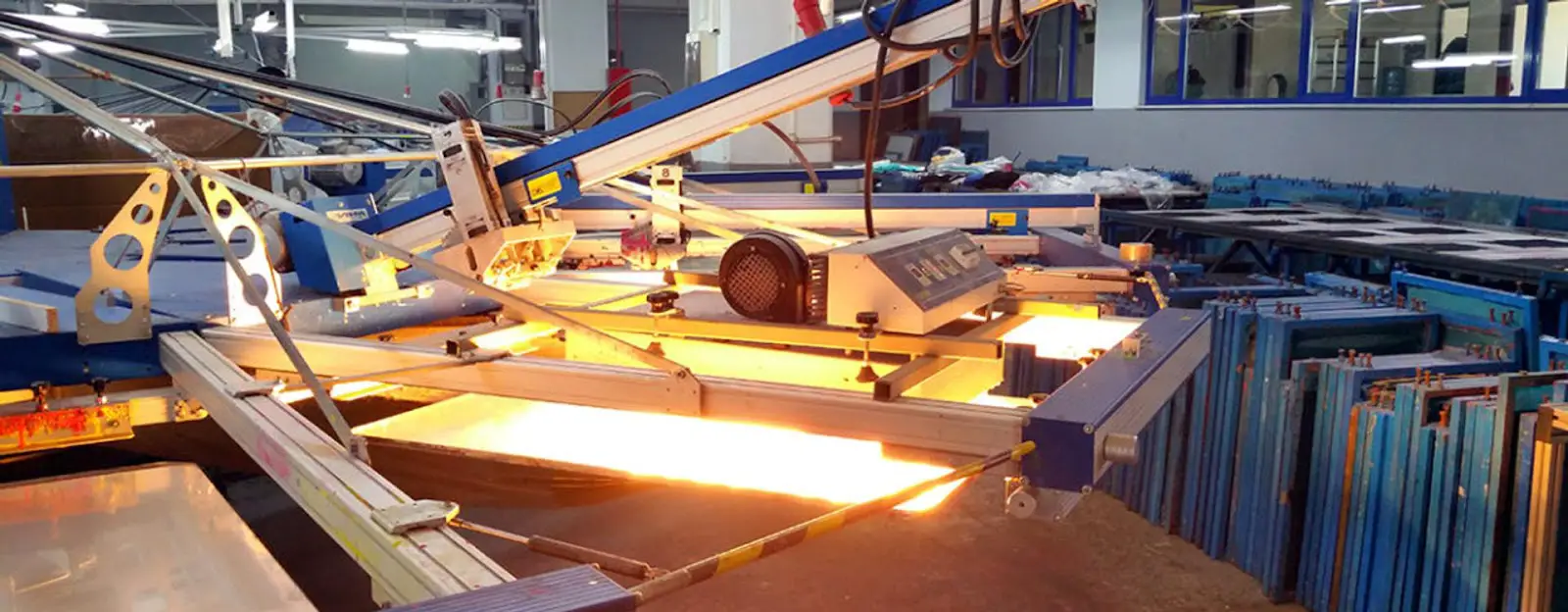

Screen printing is a multi-step process that is more than 100 years old. Simply put, the printing process involves pushing ink through a stenciled mesh screen on to a substrate, which is the t-shirt in our case.

The process begins with printing the design onto a transparent acetate film. Later the film will help to create the stencil. The next step is to coat a mesh screen with light-reactive emulsion.

The printer then places the acetate sheet with the design on top of the emulsion-covered screen, which is then exposed to bright light. The emulsion on the exposed parts of the mesh hardens under the bright light while the area covered by the design remains in a liquid state.

Once the exposed emulsion has completely hardened, the printer puts the screen under running water. This process washes off the liquid emulsion and reveals the design, effectively creating a stencil. The hardened emulsion blocks the ink from passing through the mesh screen anywhere except where you have the design.

Finally, ink is pressed through the mesh screen, passes through the design, and onto the t-shirt below.

Each color in the design requires its own separate stencil.

Why Choose Screen Printing?

There are several good reasons to choose screen printing as your preferred option.

Durable Print

Although DTG technology has come a long way over the years, screen printing reigns supreme in terms of quality. If done right, the print can last through indefinite washes. It is also not unheard of for the print design to outlast the shirt it is printed on!

There is a reason why most flags are screen printed and last for decades despite constant exposure to the elements.

Color Purity

Screen-printed designs are often described with the words vibrant, glossy, vinyl-look, and vivid, to mention but a few. Since the colors are applied directly through the screen, the designs tend to be more accurate and intense.

There is little risk of unintended saturation or dilution since you are not relying on computers to translate digital files into color outputs, as is the case with DTG. Screen printing uses true color inks, which means you get the exact colors that you wanted.

Furthermore, screen printing uses thicker layers of ink than DTG, which translates to bolder colors. This is especially important when working on darker t-shirts.

Volume Discounts

New technological advances have made screen printing faster than it was in the past. Automated presses and quick-drying ink have increased efficiency.

Making the screens may be a time-consuming process, but getting the design on the shirt takes only a few seconds. The same screens can be used hundreds or thousands of times, making screen printing the preferred printing method for bulk orders.

Direct to garment printing works on one or two shirts at a time, which can quickly rack up the cost of volume orders.

Flexible Design Placement

Since screen printing is mostly a manual process, you can choose where you want the design printed on the shirt. Trickier options like wrap-around prints and sleeve prints are easier to handle with screen printing.

Screen Printing Limitations

As with all printing methods past and present, there are a couple of limitations with screen printing.

Lower Color Count

The color count refers to the number of colors you can have on your design. Remember that each color requires a separate screen. For this reason, most printers have a color count, which can range from 4-9 different colors.

This isn’t necessarily a limitation on the process itself. Hypothetically, you can have as many colors as you have stencil screens. Printers have to decide how much the labor and materials are worth and place the necessary limitations to remain profitable.

Upfront Investment

Because a new screen needs to be custom made for each design, the screen printing setup is time-consuming and more complicated than digital printing.

Printers put minimum orders in place to make it worth their while. Print companies will typically require a minimum order of 10-25 t-shirts for screen printing. Most companies will offer discounted rates at various batch thresholds (25, 50, 100 etc.)

As a result, screen printing requires a larger upfront investment and increases the chances of ordering excess inventory.

Fewer Details on the Design

Screen printing is best for simple designs with only a few colors. The screen stenciling process is not ideal for intricate designs and images. Photorealistic images are also challenging to get right with screen printing for the same reason.

Digital printing is far better at recreating intricate designs since you are uploading a digital file that is printed on your shirt.

What is Direct-To-Garment (DTG) Printing and How Does it Work?

Direct to garment printing has been around since the 90s but has only recently became a commercially viable alternative to screen print.

The printing method is aptly named since the process involves printing designs directly onto the t-shirt using a digital printer. The fibers of the fabric absorb the ink, so the design isn’t raised, as is the case with screen printing.

The fact that the ink soaks into the garment means that it does not wash away, crack, or peel easily, as was the case with the infamous iron-on transfers that were all the rage a few years back.

You can think of direct to garment printing technology as an inkjet printer for clothes.

Why Choose Direct To Garment Printing?

There are many instances when direct to garment printing makes more sense than screen printing. Some of the advantages unique to this type of printing include:

Minimal Upfront Cost

Direct to garment printing requires minimal setup time compared to screen printing. Besides pre-treating the garments and configuring the printer, there is much less work required to start printing t-shirts.

Additionally, most DTG printers don’t have minimum order requirements. You can get a single t-shirt printed in under an hour and have it delivered on the same day. This on-demand capability is virtually impossible to find with screen printing.

Detailed Designs

Direct to garment printers are capable of firing small droplets of ink, which makes this option perfect for small and intricate designs and details. The printers can also release multiple colors at the same time. This capability makes printing intricate and multi-colored designs quicker and produces better results than screen printing.

If you want to print photorealistic images and designs, DTG is the way to go.

More Color Options

There is virtually no limitation to the number of colors you can have with DTG. You get a choice of a full spectrum of colors, and the entire design is printed at once. The result is more nuanced colors, including gradients and shading. DTG is also perfect for full-color shirts.

You can even get personal DTG printers for your home

Direct to Garment Printing Limitations

Once again, DTG is hardly a perfect printing method. You can expect a few downsides when using this process.

Possible Hit or Miss Quality

While screen printing is consistent for the most part, DTG results can be a little more varied. Factors affecting the outcome of the DTG print include the type of printer, the thickness of the ink, and the pre-treatment process, among others. You might have to shop around before you can get a printer who can closely replicate the quality you get with screen printing.

Fewer Fabric Options

While you can print on poly-blends using DTG technology, the results are less consistent than printing on 100% cotton. Poly-blends tend to have a faded or vintage look, which some people don’t like. The wash rating for DTG can also drop significantly on fabrics other than 100% cotton.

DTG can also limit where you place the designs on the t-shirt. Most direct to garment printers do not do sleeve prints and wrap around prints because of the complexity involved.

Choosing the Right Printing Method for Your T-shirt Business

Between screen printing and DTG printing, which is the right printing method for your clothing line?

The best way around this problem is to explore the ideal-case scenario for each of the printing methods.

This section is a mere guideline and not to be taken as the gospel truth. You should always make a decision based on your unique circumstances while keeping in mind this information.

Best-Case scenario for screen printing

- Ordering large batches

- Have somewhere to store inventory

- Your designs require versatile placement such as sleeve prints or wrap around prints

- Typographic designs with bold graphics

- Single color or limited colors

- Designs with transparencies

Best-Case scenario for DTG

- Single order or small batches

- Dropshipping business model

- Multi-colored or full-color designs

- Intricate or complex designs

- Gradients and shading

- Photorealistic images

Generally speaking, most print on demand services only offer DTG printing. This is mostly because most print orders are small runs. In fact, DTG technology is what made POD blow up in the way that it has today. Printing small quantities of shirts quickly and cheaply was almost unthinkable a little more than a decade ago.

Still, POD services like Bonfire and TeeSpring offer both DTG and screen printing, though there may be minimum orders. It is worth inquiring whether your preferred printer provides both options in case your print needs change down the line.

Other Printing Options for your POD Business

A great place to end this article is to briefly explore additional printing options besides DTG and screen printing.

Cut & Sew

Cut and sew is a design process where different pieces of fabric are sewn together to create the garment. The garment may be made from scratch or customized to add pockets or to alter the sleeve design.

Most rugby shirts are made with the cut and sew method. This option is perfect if you are looking for a unique design for your brand.

One of the downsides of cut & sew is that the process is labor-intensive. Because of this, the minimum orders range at around 50 units. These t-shirts can also be expensive to make, especially when compared to DTG.

Sublimation Printing

Sublimation is a printing process that transfers the design from a sublimation paper onto the garments using a combination of heat and pressure. The heat turns the ink into gas while the pressure imprints the design on the t-shirt. This process embeds the ink into the fabric rather than have it sit on the shirt.

Sublimation printing offers you complete control of where you want to place your design on the garment. This method also works great for putting multiple designs on the same t-shirt. You can combine sublimation printing with cut and sew to create truly unique designs.

Embroidery

While not precisely a printing method, embroidery is also worth looking into as a t-shirt design element. Embroidery involves stitching the design on to the fabric.

Embroidery designs far outlast printed designs but work best on thicker fabrics like hoodies, sweatshirts, and polo shirts.

It is worth noting that some print on demand companies like Printful offer these additional printing methods on top of DTG printing.